In part 9 of our 10-part series on designing a power supply, we’re focusing on EMI and RFI testing. This stage is often overlooked due to difficulty and cost. However, ignoring this step can lead to unpleasant surprises and delays as your deadline looms. We also strongly recommend testing for EMC issues early in the design process to avoid unnecessary board turns and missed timelines.

So, grab your spectrum analyzer and your pre-defined EMI compliance mask and catch those pesky EMI problems before you arrive at the test house later on.

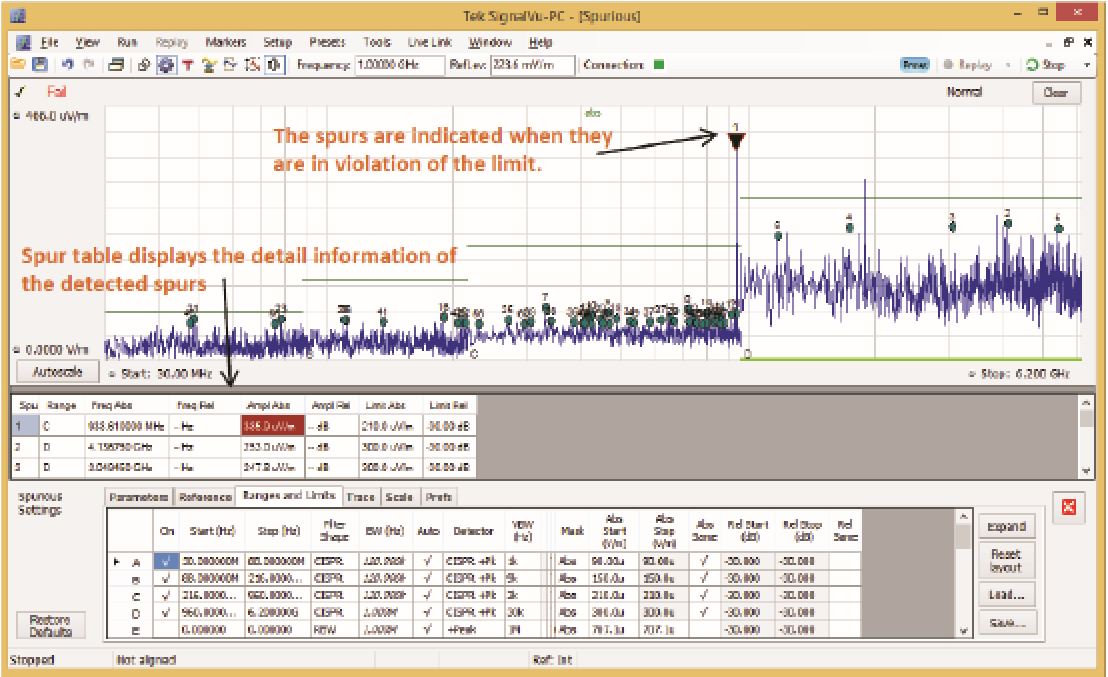

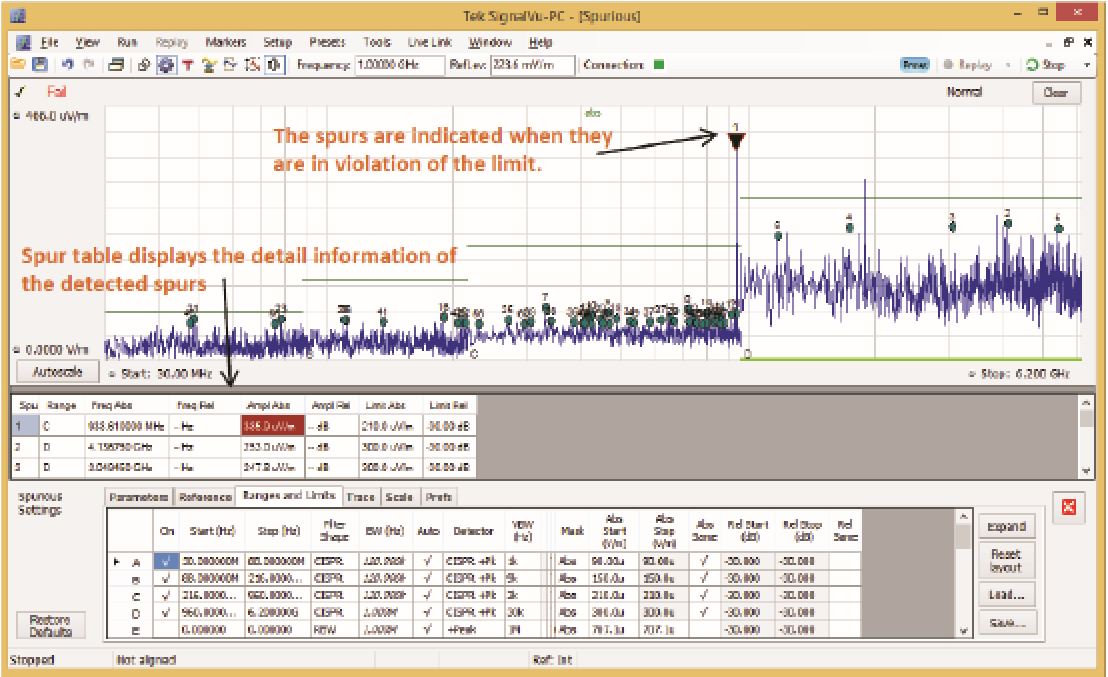

The Tektronix RSA306B spectrum analyzer is a great option. This affordable USB-based instrument provides real-time spectrum analysis, while allowing you to spot short-duration EMI bursts. This instrument’s long recording time also enables you to capture infrequent bursts.

Example of pre-compliance EMI scan with an RSA306B real-time spectrum analyzer

To quickly localize sources of EMI. We suggest using a mixed domain oscilloscope (MDO) with a built-in spectrum analyzer and near-field probes. Armed with your trusty MDO and a schematic, you can easily measure spectral peaks and deduce root causes.

When evaluating MDOs, it’s hard to top the MDO4000C because it lets you view your design’s performance in time and frequency domains all on one instrument. The MDO4000C comes complete with powerful trigger and search and analysis tools that allow you to zero in on analog and digital anomalies. This instrument also enables you to decode serial buses alongside waveforms and view the RF spectrum at any time. Lastly, SignalVu-PC software, which is included in the instrument, enables you to perform extensive analysis and troubleshooting on Wi-Fi and Bluetooth wireless signals.

Example of EMI troubleshooting with synchronized and spectrum traces on an MDO4000C oscilloscope

For hands-on guidance and performing EMI test and troubleshooting, you’ll want to download the Practical EMI Troubleshooting application note.

In the final part of this series, we’ll look at design validation to help you prepare for the next turn of your design.

See more in the 10-part series:

Part 1: Component Selection and Characterization for Power Supply Design

Part 2: Low-Voltage DC Circuit Power-On Test

Part 3: High-Voltage AC Circuit Power-On Test

Part 4: Digital and Analog Control Circuit Debug

Part 5: Testing Power Stage Switching Characteristics

Part 6: Switching and Conduction Loss Testing

Part 7: Power Supply Specification Check

Part 8: Power Line Compliance Testing